As we look ahead to 2026, the food contract manufacturing industry is poised for significant changes. Experts predict innovative trends will reshape how companies develop and produce food products. "Adaptability is key in food contract manufacturing," says Dr. Alice Chen, a leading expert in food supply chains. Her insight emphasizes the importance of evolving with market demands.

In recent years, consumers have shifted towards healthier options. This pushes manufacturers to rethink ingredients and processes. Companies are experimenting with alternative proteins and sustainable sourcing. The challenge lies in balancing cost, quality, and consumer expectations. Many firms may struggle to adapt, leading to potential setbacks.

Moreover, technological advancements will continue to play a crucial role. Automation and data analytics can enhance efficiency but come with high initial investments. Small to medium-sized enterprises might find it hard to keep pace. It’s a time of reflection. Are we ready to embrace these changes, or are we locked in old habits? The food contract manufacturing landscape is changing, and companies must be prepared to respond effectively.

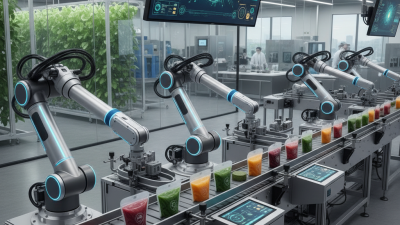

The landscape of food contract manufacturing is evolving rapidly. In 2026, emerging technologies will play a pivotal role in shaping the industry. Automation is gaining traction. Companies are adopting robotic systems to enhance productivity and efficiency. These systems can streamline production lines and reduce labor costs.

Digital technologies are also making waves. Big data analytics allows manufacturers to forecast demand. Understanding market trends helps in making informed decisions. Predictive analytics can fine-tune production schedules. This ensures that the right amount of product is available at the right time.

Tip: Embrace small-scale pilot programs to test new technologies before full implementation. This minimizes risks. Assessing real-time data can uncover potential issues early.

Another notable trend is the rise of smart packaging. Intelligent packaging can improve food safety and tracking. This technology ensures products stay fresh longer. It also enhances consumer engagement through QR codes and augmented reality.

Tip: Focus on sustainability. Consumers favor businesses that prioritize eco-friendly practices. Explore biodegradable materials and waste-reducing technologies. Reflect on ways to reduce your overall environmental footprint.

Sustainability is transforming food manufacturing. A recent report indicates that over 70% of consumers prefer sustainable products. This shift forces manufacturers to adopt green practices. Energy-efficient equipment is becoming the norm. Many companies aim to cut energy use by 30% by 2026.

Water usage is another critical area. Innovations in water recycling are essential. Some facilities are reducing water waste by up to 50%. As consumers demand transparency, manufacturers must disclose sourcing practices. More than 60% of consumers want this information on labels, pushing companies to comply.

Challenges remain. Implementing sustainable practices can be costly. Many manufacturers face budget constraints, making green upgrades difficult. Training staff on these new methods takes time. Additionally, not all suppliers prioritize sustainability. This creates inconsistencies in production standards. Food producers must navigate these complex issues to meet growing consumer expectations.

Consumer preferences are rapidly evolving, significantly impacting food contract manufacturing. Today, shoppers seek transparency in sourcing and production methods. They want to know where ingredients come from. This demand pushes manufacturers to adopt clearer labeling practices. Consumers favor locally sourced ingredients. It’s a growing trend that can't be ignored.

Health-conscious choices are also influencing these decisions. Consumers are gravitating towards clean and organic products. The desire for natural ingredients is driving innovation in manufacturing processes. However, not all manufacturers are equipped to meet these expectations. There are challenges in scaling production while maintaining quality. This gap often leads to inconsistencies in product offerings.

Sustainability is another key factor. Environmental concerns are shaping consumer choices. Brands that prioritize eco-friendly practices appeal more to buyers. Yet, many manufacturers struggle with the transition to sustainable methods. This is a complex issue, requiring time and investment. Balancing profitability and sustainability remains a significant challenge for food contract manufacturers.

As we move toward 2026, food contract manufacturers must navigate a rapidly changing regulatory environment. New food safety regulations are emerging globally. These rules aim to enhance product safety and transparency. Manufacturers will need to adapt their processes accordingly. This can mean updated training for staff and revamped quality control measures.

Compliance with these regulations is crucial, but it can be daunting. Changes may require significant investments in technology and processes. Some companies may struggle to keep pace. Others might find themselves at a competitive disadvantage if they fail to comply. It's also essential to stay informed about shifts in consumer preferences. Understanding these dynamics will shape manufacturing strategies moving forward.

Collaboration with regulatory bodies can be beneficial. By engaging in dialogue, manufacturers can better understand expectations. However, not every manufacturer is equipped or willing to take this step. This gap can lead to inconsistencies in compliance. Ultimately, the ability to adapt to regulatory changes will define success in the coming years. Manufacturers must learn to embrace uncertainty.

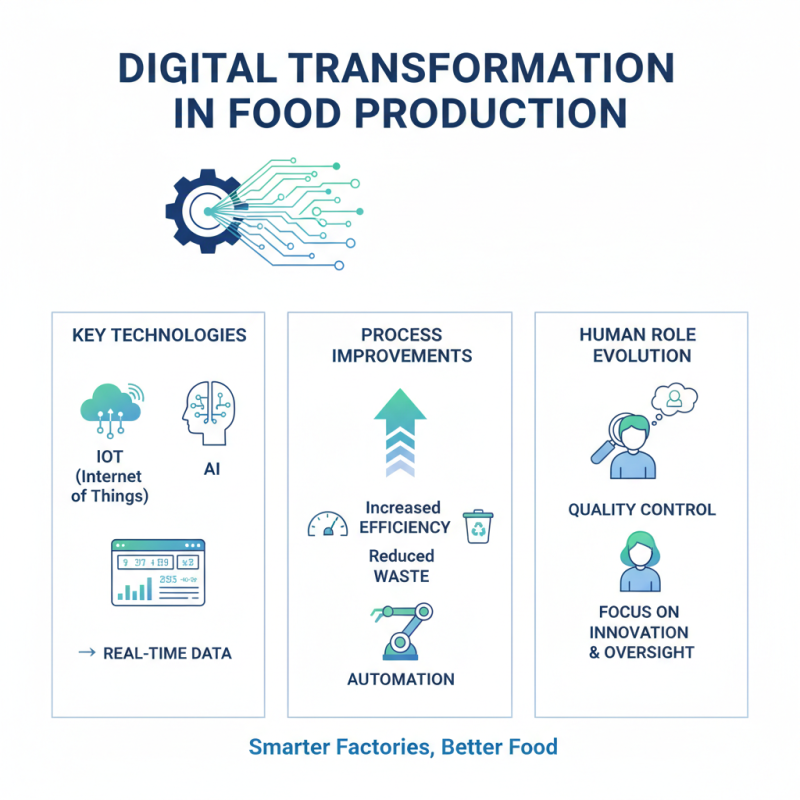

Digital transformation is reshaping food production processes. Technologies like IoT and AI are driving this change. Factories now rely on real-time data. This increases efficiency and reduces waste. Automation is a big part of this shift. Machines handle repetitive tasks, allowing human workers to focus on quality control.

However, not all companies adapt well to these changes. Some struggle with integration and employee training. The transition can be bumpy. Analytics tools require new skills that some staff may lack. Adjustments to workflows might disrupt established routines. It's essential for companies to address these gaps to harness the full potential of digital tools.

Data-driven decision-making is another crucial aspect. By analyzing consumer trends, manufacturers can create products that meet market demands. Yet, there is a risk in over-reliance on technology. Human oversight is vital to catch errors that machines might miss. Balancing automation with human insight will be key in the coming years.

TO GET STARTED OR FOR A FREE QUOTE CALL 888.454.3466