Selecting the right beverage co-packers is a crucial decision for any business looking to streamline production and ensure quality. As the beverage industry continues to grow and evolve, the demand for effective co-packing solutions has increased significantly. Beverage co-packers play a vital role in transforming your concept into a market-ready product, providing various services that include bottling, labeling, and packaging. Understanding your specific needs and the capabilities of potential co-packers can make all the difference in the success of your beverage brand.

When exploring options for beverage co-packers, it is essential to consider factors such as their experience with different beverage types, production capacity, and quality control measures. These elements not only impact the efficiency of the production process but also the overall quality of the final product. In this guide, we will delve into important criteria and best practices for choosing the right beverage co-packers that align with your business goals and help to elevate your beverage offerings in a competitive market. By making informed decisions, you can secure a partnership that fosters growth and innovation in your business.

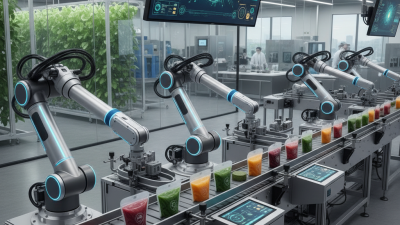

In the beverage industry, co-packers play a crucial role in transforming innovative ideas into market-ready products. They are third-party manufacturers that help businesses produce their beverages efficiently, allowing entrepreneurs to focus on branding, marketing, and distribution. By partnering with co-packers, companies can leverage their expertise in production processes, including sourcing raw materials, managing inventory, and ensuring compliance with food safety regulations. This collaboration is essential for businesses aiming to scale rapidly without incurring substantial upfront costs on equipment and facilities.

Understanding the importance of co-packers is vital for any beverage business. They not only provide the technical know-how but also offer flexibility in production capabilities, which can be particularly beneficial for startups and small enterprises. Co-packers can adapt to varying batch sizes, enabling brands to test new flavors or respond to seasonal demand without the financial risk of overproduction. Additionally, their established supply chain networks can help expedite the launch of new products, ensuring that businesses remain competitive in a fast-paced market. By choosing the right co-packer, beverage companies can enhance their operational efficiency and focus their resources on growing their brand.

| Criteria | Description | Importance |

|---|---|---|

| Experience in Industry | Look for co-packers with a proven track record in the beverage sector. | High |

| Production Capacity | Ensure they can meet your production needs, scalability is essential. | High |

| Certifications | Check for industry certifications, such as ISO or FDA compliance. | Medium |

| Flexibility | Assess their willingness to accommodate custom recipes and formulations. | High |

| Quality Control Measures | Review their quality assurance processes to ensure product consistency. | High |

| Cost Structure | Understand their pricing model and how it fits in your budget. | Medium |

| Location | Consider the proximity to your distribution network for logistics efficiency. | Medium |

| Customer Support | Evaluate the level of support and communication throughout the process. | High |

When selecting the right beverage co-packer for your business, several key factors should be evaluated to ensure that your product stands out in a competitive marketplace. First, it is essential to assess the co-packer's capabilities, including their production capacity, technology used, and flexibility in managing different beverage types. According to a recent industry report by Grand View Research, the beverage co-packing market is projected to grow at a CAGR of 5.2% from 2021 to 2028, indicating a significant demand for reliable co-packers who can adapt to evolving consumer preferences.

Another vital aspect to consider is the quality assurance processes in place. With increasingly health-conscious consumers demanding transparency, co-packers must maintain rigorous quality control standards. The American Society for Quality states that companies with robust quality assurance protocols tend to reduce production costs and improve customer satisfaction rates. Make sure to request documentation related to their quality practices and certifications, as this will directly impact the integrity of your product.

**Tip:** When evaluating potential co-packers, conduct site visits to gain insight into their operations and quality control. This on-site assessment can reveal a lot about their capabilities and commitment to food safety.

Lastly, consider the financial implications, including pricing structures and minimum order quantities. Establishing a clear understanding of your budget relative to the co-packer's costs can prevent future discrepancies. Research illustrates that effectively managing operating costs can enhance overall profitability; in fact, a report by IBISWorld highlights that beverage manufacturing firms that optimize their supply chains can boost their profit margins by up to 15%.

**Tip:** Always obtain quotes from multiple co-packers to compare services and negotiate terms that align with your business goals.

The beverage industry has witnessed a remarkable shift towards co-packing services, driven by evolving consumer preferences and an increasing focus on product variety. As health-conscious shoppers seek more diverse options—ranging from organic juices to functional drinks—businesses are compelled to adapt rapidly. This growing demand for customized beverages has led many companies, including startups and established brands, to consider partnering with co-packers who can efficiently handle production while maintaining flexibility in formulation and packaging.

As consumer trends continue to evolve, beverage co-packers are enhancing their capabilities to meet these needs. Many now offer a wide range of packaging solutions, including eco-friendly materials and innovative designs, which are crucial for standing out in a crowded market. Moreover, the rise of e-commerce has intensified the urgency for brands to adapt their logistics and distribution strategies, further increasing reliance on co-packing partners. By leveraging the expertise of these co-packers, companies can streamline their operations, allowing them to focus on marketing and brand development while ensuring they meet the latest market demands.

When choosing beverage co-packers, it is crucial to assess their quality standards and certifications to ensure they meet the specific needs of your business. According to the Global Co-Packing Market Report 2023, a significant 65% of companies prioritize certification adherence when selecting co-packers. Certifications such as ISO 22000, which focuses on food safety management systems, and Hazard Analysis and Critical Control Points (HACCP), play a key role in safeguarding product quality and consumer trust. These standards help to mitigate risks associated with contamination and maintain consistent product quality across batches.

Additionally, the quality management systems employed by co-packers can significantly impact the production process. A report from the Beverage Industry Association indicates that co-packers with recognized quality certifications are 40% more likely to uphold strict quality control measures. This not only enhances product safety but also reduces potential recalls, which can have costly implications. As businesses navigate an increasingly competitive market, it is essential to partner with co-packers who demonstrate a robust commitment to quality, ensuring that their facilities are regularly audited and compliant with industry regulations. By prioritizing these elements during the selection process, companies can fortify their product line and cultivate long-lasting consumer relationships.

When budgeting for co-packing services in beverage production, understanding the cost structures involved is critical for maintaining profitability. A recent industry report from Beverage Industry Insights reveals that co-packing services can vary widely in cost, influenced by factors such as order volume, complexity of the product, and packaging choices. For instance, a standard beverage co-packing charge may range from $0.50 to $2.00 per unit, depending on the scale of production and the specific services included, such as bottling, labeling, and distribution.

Moreover, it is essential to consider the hidden costs that may arise during the co-packing process. A study by the Co-Packing Association highlights that companies often overlook expenses like quality assurance testing, ingredient sourcing, and compliance regulations, which can add an additional 15-30% to the overall budget. Building a comprehensive cost analysis framework allows businesses to evaluate multiple co-packers effectively and choose partners that align with their financial goals while ensuring product quality and operational efficiency.

TO GET STARTED OR FOR A FREE QUOTE CALL 888.454.3466