The beverage manufacturing industry is undergoing a significant transformation, driven by the rapid advancement of digital technologies. According to a recent report by McKinsey, the global beverage market is projected to reach $1.9 trillion by 2025, reflecting a CAGR of over 4%. This growth is increasingly influenced by digital trends that enhance operational efficiency, improve supply chain management, and elevate consumer engagement. In an era where consumer preferences shift rapidly and sustainability becomes paramount, beverage manufacturers are leveraging innovative solutions to stay competitive and responsive to market demands.

As Industry 4.0 continues to redefine manufacturing processes, the integration of automation, artificial intelligence, and the Internet of Things (IoT) is becoming essential for beverage companies. A study by Deloitte indicates that 60% of beverage manufacturers are investing in smart technologies to streamline their production lines and improve quality control. By implementing data analytics and automation, companies are not only boosting productivity but also enhancing their ability to tailor products to meet the increasingly personalized preferences of consumers. As we explore the top digital trends transforming beverage manufacturing in 2023, it becomes clear that those who embrace these changes will be better positioned to thrive in a rapidly evolving market landscape.

Digital transformation is reshaping the landscape of beverage manufacturing, driving efficiency and innovation across various processes. According to a report from the World Economic Forum, the adoption of Industry 4.0 technologies is projected to boost productivity in the manufacturing sector by up to 30% by 2030. In the beverage industry, this means leveraging advanced data analytics, automation, and the Internet of Things (IoT) to enhance production capabilities and optimize supply chains, ultimately reducing costs and increasing agility.

The integration of smart technologies facilitates real-time monitoring of production lines, enabling manufacturers to swiftly respond to trends and consumer demands. Recent findings from a McKinsey & Company study indicate that companies employing automation and data analytics in their operations can achieve a 20-25% reduction in operational costs while significantly improving product quality. Furthermore, sustainable practices powered by digital innovations help minimize waste and energy consumption, aligning with the increasing consumer preference for eco-friendly products. As the beverage industry continues to evolve, the emphasis on digital transformation is essential for staying competitive in a rapidly changing market.

In 2023, the beverage industry is experiencing a significant transformation driven by emerging technologies that are redefining production processes, supply chain management, and consumer engagement. One of the most significant trends is the adoption of artificial intelligence (AI) and machine learning, which optimize manufacturing efficiencies by predicting maintenance needs and enhancing quality control. These technologies enable producers to monitor operations in real-time, minimizing waste and ensuring consistency across batches, ultimately leading to higher productivity and lower costs.

Additionally, the integration of IoT devices in beverage manufacturing is revolutionizing the way companies collect and analyze data. Smart sensors throughout the production line provide valuable insights into equipment performance and environmental conditions, allowing for proactive adjustments and faster decision-making.

Furthermore, advancements in sustainable practices, such as blockchain technology, are enhancing traceability in the supply chain, ensuring that ingredients are sourced responsibly and that consumers can access transparency about their beverages. As these technologies continue to evolve, they are set to create a more agile and responsive beverage industry, capable of meeting the demands of modern consumers.

The beverage manufacturing industry is witnessing transformative sustainability trends in 2023 that are shaping production practices. With an increasing consumer awareness surrounding climate change and environmental impact, manufacturers are integrating sustainable practices from sourcing to distribution. This includes prioritizing renewable resources, reducing carbon footprints, and adopting eco-friendly packaging solutions. The adoption of lifecycle assessment tools allows companies to optimize their operations and minimize waste, ensuring that sustainability is embedded at every stage of production.

In addition to operational efficiencies, innovation in ingredients and processes is also at the forefront of sustainable beverage production. Many manufacturers are exploring plant-based alternatives and utilizing upcycled materials to create new products, thereby contributing to a circular economy. Furthermore, smart technology is being leveraged to monitor resource usage meticulously, helping businesses make data-driven decisions that promote sustainability. As the industry evolves, embracing these trends not only meets regulatory requirements but also aligns with the growing consumer demand for ethical and environmentally responsible products.

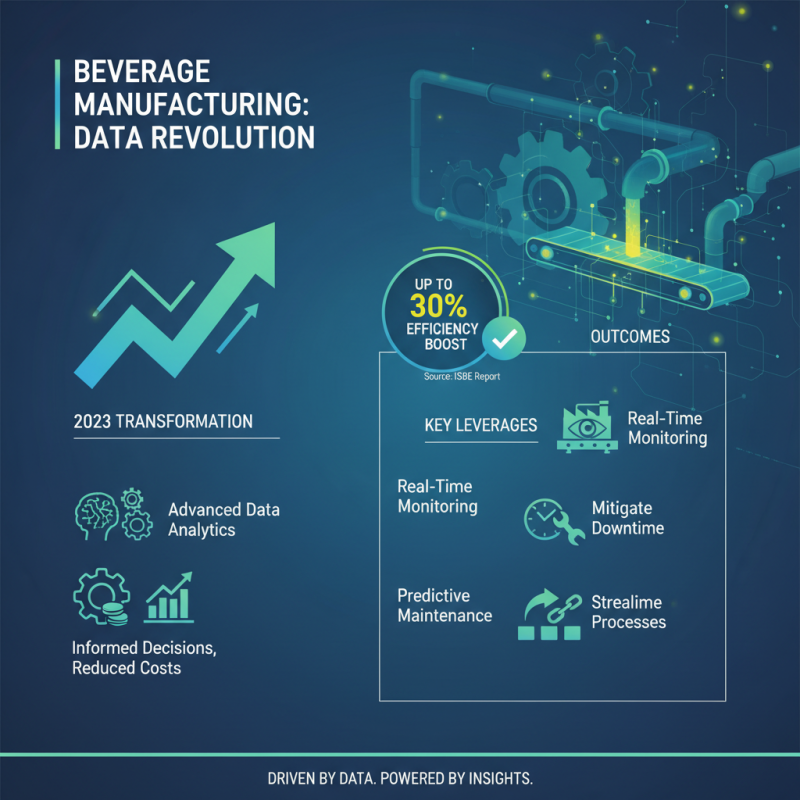

In 2023, the beverage manufacturing landscape is witnessing a significant transformation driven by advanced data analytics. By leveraging data, manufacturers can make informed decisions that enhance production efficiency and reduce operational costs. According to a recent report from the International Society of Beverage Engineers, companies utilizing data analytics have improved their manufacturing efficiency by up to 30%. This improvement comes from real-time monitoring and predictive maintenance, enabling manufacturers to mitigate downtime and streamline processes.

Embracing data analytics allows manufacturers to analyze production patterns, consumer preferences, and supply chain dynamics, which are essential for aligning inventory with market demands. A study from the Beverage Industry Association highlights that manufacturers who adopt data-driven decision-making can achieve a 15% reduction in waste and improve product quality, ultimately leading to increased customer satisfaction. This capability to adapt swiftly to changing market trends not only boosts profitability but also safeguards long-term sustainability.

**Tip**: Implement a centralized data management system to facilitate better collaboration and data sharing across departments. This approach enhances visibility into production processes, allowing for quicker adjustments and optimization.

**Tip**: Invest in training for staff to ensure they can effectively leverage new analytics tools. Skilled personnel can uncover insights that enhance both efficiency and innovation, driving continuous improvement in manufacturing processes.

As we navigate through 2023, the beverage manufacturing sector is witnessing a profound transformation driven by consumer-centric innovations. Recent data from the Beverage Industry Report indicates that 75% of consumers are looking for healthier, more sustainable options, prompting manufacturers to adapt their offerings. This shift is not merely about product development; it encompasses the entire supply chain, aiming to enhance transparency and sustainability. For instance, real-time tracking systems are being implemented to ensure ingredient sourcing is both ethical and environmentally friendly, addressing growing consumer demands for accountability.

Moreover, technology is playing a significant role in shaping these consumer preferences. According to a survey by the International Food Information Council, 60% of consumers are influenced by digital marketing and online reviews when making beverage choices. This trend highlights the importance of leveraging data analytics and artificial intelligence to understand consumer behavior better. Manufacturers are increasingly adopting innovative packaging solutions that not only preserve product quality but also engage consumers through interactive elements while highlighting sustainability credentials. As the industry continues to evolve, it remains essential for beverage manufacturers to stay attuned to these trends and invest in innovation that resonates with health-conscious and environmentally aware consumers.

| Trend | Description | Impact on Industry | Consumer Benefits |

|---|---|---|---|

| Sustainability Initiatives | Adopting eco-friendly packaging and reducing carbon footprint. | Enhances brand image and meets regulatory standards. | Access to greener products and participation in sustainability. |

| Personalization | Offering customizable flavors and experiences for consumers. | Increases customer loyalty and satisfaction. | Tailored products that fit individual tastes. |

| Smart Technology | Integration of IoT for monitoring and optimizing production processes. | Improves efficiency and reduces waste in operations. | Higher quality products and potentially lower prices. |

| E-commerce Expansion | Growth of online sales channels for beverages. | Increases market reach and consumer convenience. | Easy access to products from home. |

| Health Consciousness | Development of low-sugar, functional, and health-focused beverages. | Responds to growing consumer health trends. | Access to healthier beverage options. |

| Blockchain Transparency | Use of blockchain to trace ingredient sourcing. | Increases trust and authenticity in the market. | Informed purchase decisions based on ingredient transparency. |

| Augmented Reality Experiences | Employing AR for marketing and consumer engagement. | Innovative marketing strategies to attract consumers. | Engaging and interactive experiences with products. |

| Data-Driven Marketing | Analyzing consumer data to tailor marketing strategies. | Fosters deeper consumer connections and targeted promotions. | More relevant marketing and personalized offers. |

| Remote Monitoring Systems | Implementation of remote monitoring for quality control. | Ensures consistent product quality and reduces downtime. | Consistently high-quality beverages. |

| Adaptive Supply Chains | Flexibility in supply chain to adapt to market changes. | Improves resilience and responsiveness to demand. | Better availability of products according to consumer needs. |

TO GET STARTED OR FOR A FREE QUOTE CALL 888.454.3466